Right-Angle Sealing & Suction Labeling Machines for Food Factories | Double Win

For food factories—from small-batch artisanal producers to mid-sized snack and sauce brands—packaging is more than just “wrapping goods”: it’s about preserving freshness, meeting global safety regulations, and keeping up with production deadlines.

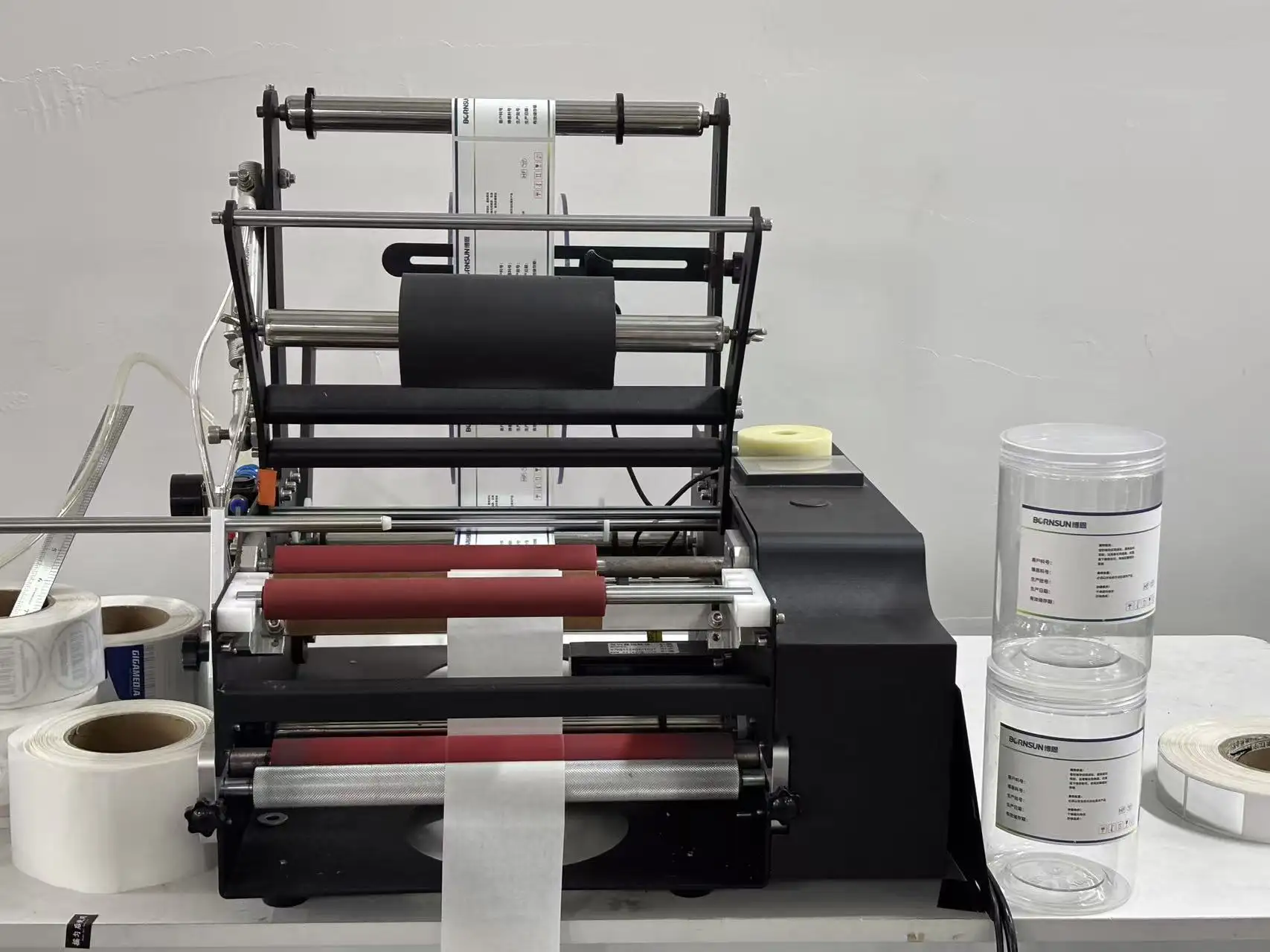

Manual sealing and labeling often fall short: leaky seals ruin perishable items, crooked labels trigger compliance fines, and slow handwork delays shipments. That’s why two semi-automatic tools have become non-negotiable upgrades for food packaging lines: the Semi-Automatic Right-Angle Sealing Machine(产品详情页) and Semi-Automatic Right-Angle Suction Flat Labeling Machine(产品详情页).

Why Food Factories Need These Semi-Automatic Tool

Food production has unique, non-negotiable demands:

- Hygiene first: Equipment must be food-safe, easy to clean, and corrosion-resistant.

- Flexible packaging: Adapt to boxes, pouches, jars, and flat-surface containers (common in snacks, sauces, and baked goods).

- Cost control: SMEs can’t afford fully automatic lines—but need to cut labor costs.

- Consistency: Seals must be airtight; labels must be precise (for traceability laws like the U.S. FDA Food Labeling Regulations(外部链接) and EU 1169/2011(外部链接)).

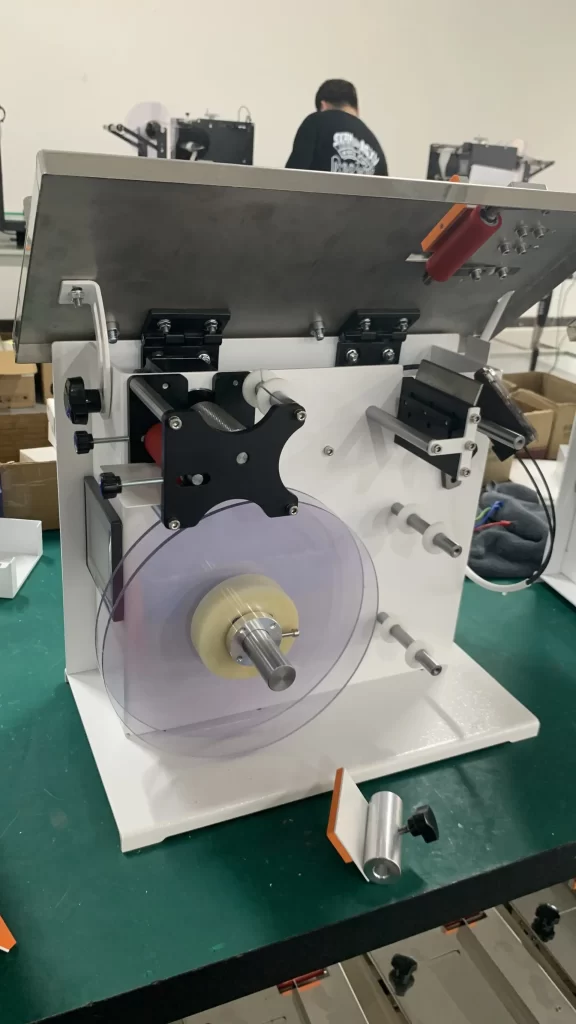

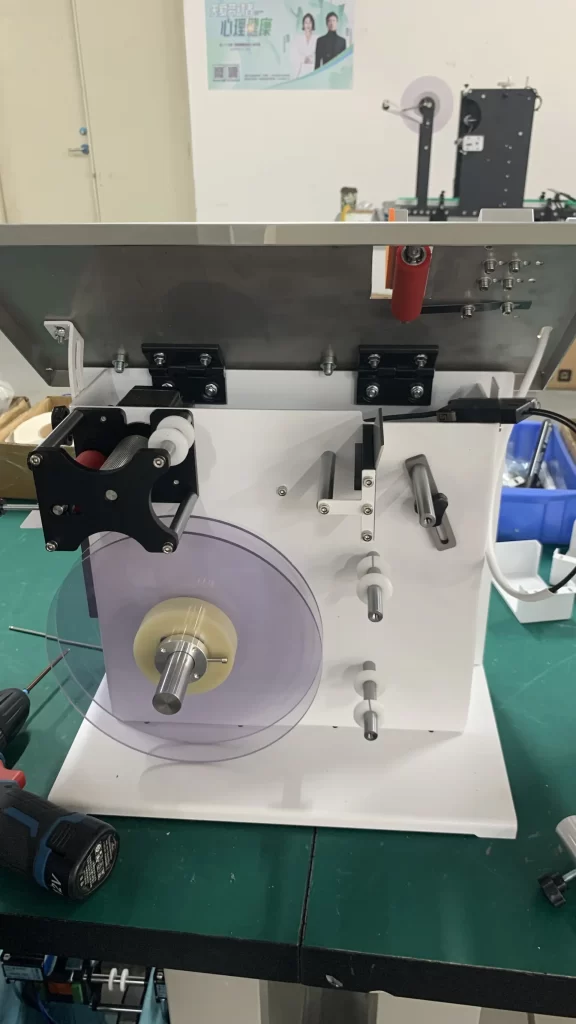

Product 1: Semi-Automatic Right-Angle Suction Flat Labeling Machine (Precise Labeling for Food Packaging)

✅ Food-grade 304 stainless steel body: Rust-resistant, easy to wipe clean, and compliant with food contact safety standards✅ ±1 mm precise labeling: Right-angle suction technology ensures flat, neat application—perfect for sealing transparent labels and product info tags on snack pouches (like the ones in the image)✅ 40 units per minute efficiency: Auto-aligns and applies labels after manual feeding, cutting manual labeling time by 60%✅ Versatile for food packaging: Fits sealing transparent labels, barcode tags, and ingredient labels; compatible with snack pouches, cartons, and small food containers✅ Low-maintenance design: Compact size (60x40x80cm) and detachable label rollers for easy cleaning (ideal for frequent use in snack production lines)

Product 2: Semi-Automatic Right-Angle Suction Flat Labeling Machine (Precision for Compliance)

Food labels aren’t just branding—they’re legal requirements. This machine eliminates manual labeling errors:✅ ±0.3mm precision: Suction technology applies labels (self-adhesive, moisture-proof) flat, straight, and bubble-free (meets global traceability rules).✅ Food-safe label compatibility: Works with oil/moisture-resistant labels (for refrigerated/frozen goods) + supports date/batch barcodes.✅ 2-minute SKU switches: Adjust label size (10-120mm width; 15-80mm height) for multi-product food lines.✅ 50 units/minute speed: Faster than manual labeling (10-15 units/minute) without automatic-line costs.✅ Hygienic design: Smooth surfaces + detachable rollers for easy cleaning (no contamination risks).

Ideal food uses: Cereal boxes, sauce jars, snack packs, organic food containers.

Customer Success Story: 30% Efficiency Boost for a Small-Batch Bakery

Guangzhou Xinyue Bakery (a 20-person artisanal bread producer) faced two issues:

- Manual sealing of bread boxes caused 15% of loaves to go stale early (leaky seals).

- Hand-labeling took 2 hours per batch (crooked labels led to 2 FDA compliance warnings in 2024).

After adopting our Semi-Automatic Right-Angle Sealing Machine and Suction Flat Labeling Machine in March 2025:

- Stale bread rates dropped to 2% (airtight seals extended shelf life by 25%).

- Packaging labor time per batch fell to 40 minutes (66% faster).

- No further compliance warnings (labels met FDA precision standards).

“These machines let us focus on baking, not fixing packaging mistakes,” said Xinyue’s production manager.

Why These Two Semi-Automatic Labeling Machines Work for Food Factories

- Cost-effective scaling: Semi-automatic labeling machines = lower upfront costs than fully automatic labeling lines (perfect for growing food SMEs).

- Compliance protection: Precise, bubble-free labels (±0.3mm accuracy) meet global food labeling regulations (avoids fines for misaligned/illegible labels).

- Labor savings: Reallocate 50-60% of manual labeling staff to core production tasks (e.g., food quality checks).

- Space-friendly: Compact footprints of these labeling machines fit small workshop lines (no renovations needed to integrate).

- Food-grade durability: 304 stainless steel bodies stand up to frequent cleaning (critical for food packaging environments).environments).

Ready to Upgrade Your Food Packaging Line?

Our Semi-Automatic Right-Angle Sealing & Labeling Machines come with:

- Global 24/7 technical support

- FDA/CE/ISO 9001 food safety certifications

- Customizable size options for unique packaging

- Free demo videos & on-site training (bulk orders)

Email sales@39309wen.gmail.com or fill out our 在线咨询表单 to get a personalized quote—let’s boost your food packaging efficiency, one seal/label at a time.

Recent Posts

-

Best Semi-Automatic Labeling Machine for Food Factories: Boost Efficiency & Cut Costs

December 26, 2025

-

Semi-Automatic Labeling Machine: The Small-Business Guide to Picking the Right One (3 Use Cases + 4 Costly Mistakes)

December 11, 2025

-

Cost-Effective Labeling Machine Takes Industry by Storm: ±0.05mm Precision at 40% Lower Price

December 5, 2025