Home »

Semi-Automatic Labeling Machine: The Small-Business Guide to Picking the Right One (3 Use Cases + 4 Costly Mistakes)

- Intro BlockSpending hours hand-labeling artisanal jam jars or small-batch skincare bottles—only to end up with crooked tags and sore wrists?

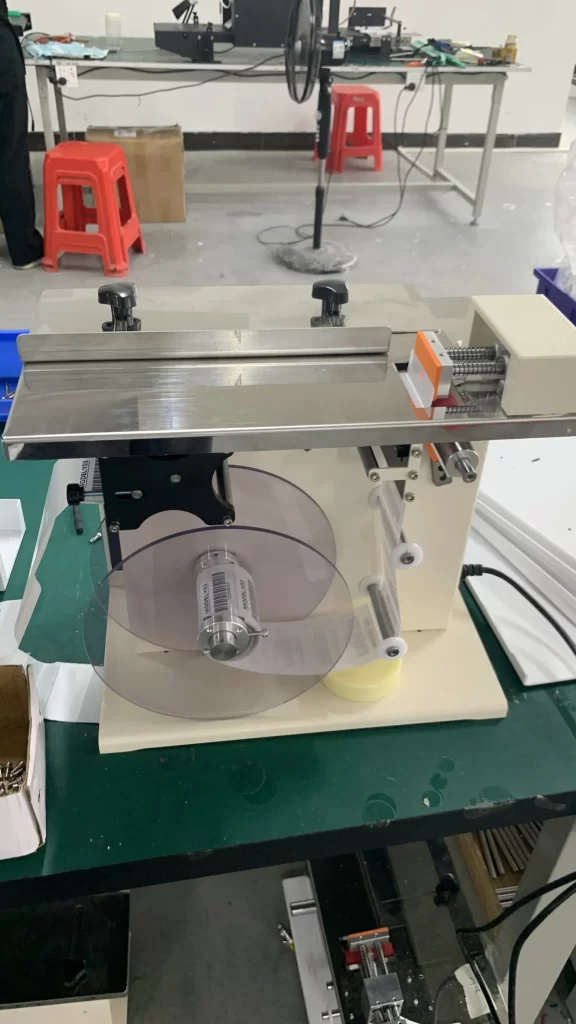

For small businesses, a fully automatic labeling line is too pricey (and overkill for 500–5,000 units/day). Enter the semi-automatic labeling machine: it cuts labeling time by 3x, keeps costs under $7k, and works for messy, variable workflows. But pick the wrong model, and you’ll end up with jammed labels or wasted supplies. This guide breaks down exactly which labeler fits your work (and what to skip). - Use Case 1: Artisanal Food & Beverage (e.g., craft beer cans, homemade honey jars)Ideal Machine: Tabletop Manual-Adjust Semi-Automatic LabelerWhy it works:

- No tech learning curve: Twist a dial to align labels (no clunky software—perfect for part-time team members)

- Switches packaging fast: Swap from 12oz beer cans to 8oz honey jars in 5 minutes (no custom fixtures needed)

- Budget-friendly: Entry models start at $4,200—cheap enough for micro-batch producers testing new products

- Use Case 2: Small-Batch Cosmetics (e.g., travel-size lotion tubes, glass serum jars)Ideal Machine: Pneumatic-Clamp Semi-Automatic LabelerWhy it works:

- Brand-safe precision: Pneumatic clamps hold irregular-shaped tubes/jars steady, so labels sit ≤1mm off-center (no lopsided tags that turn customers away)

- Handles sticky materials: Works with glossy, waterproof labels common in skincare (no peeling mid-shipment)

- Scales with growth: Handles 2,000–5,000 units/day—enough to keep up as your Instagram shop gains traction

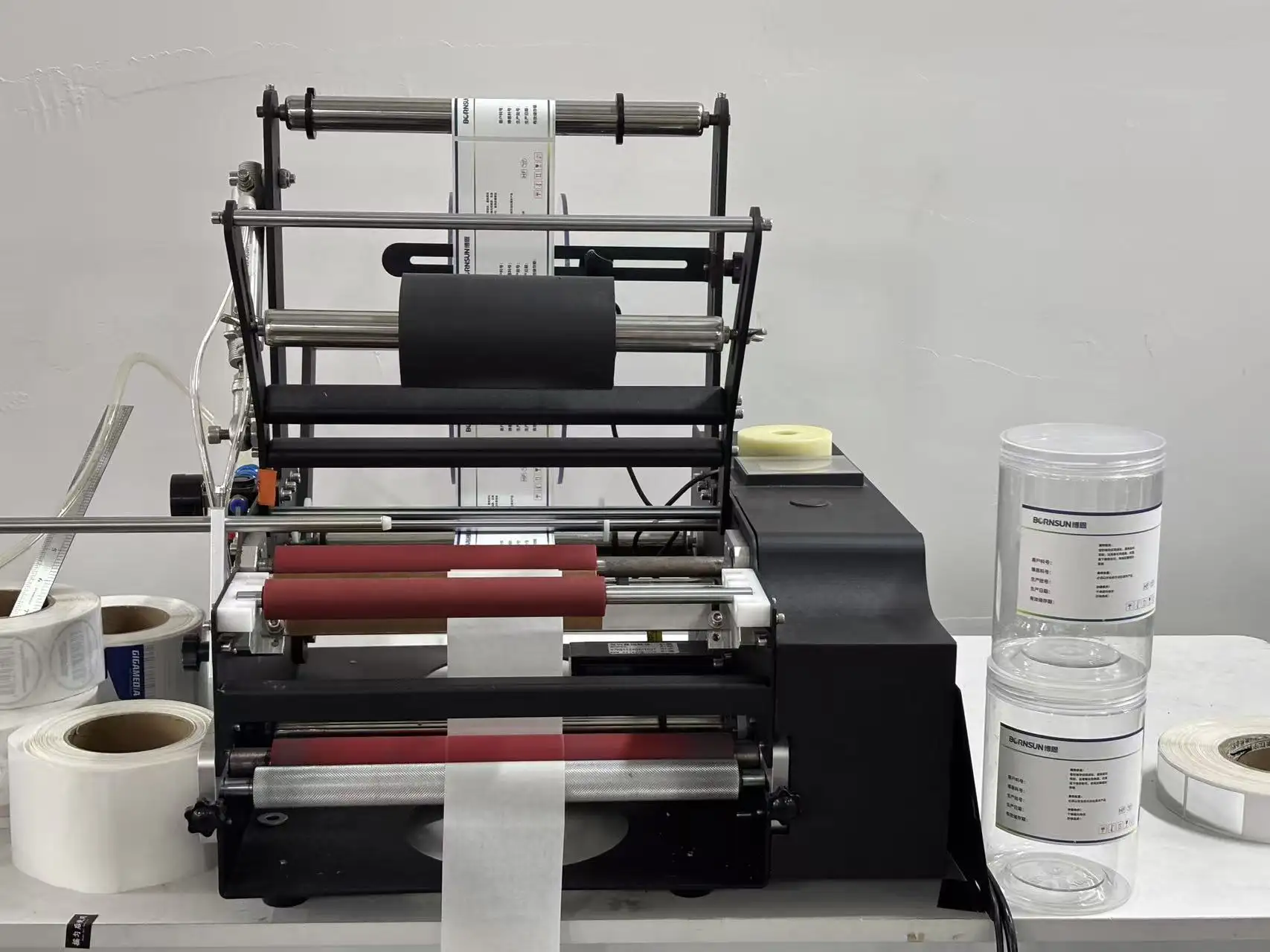

- Use Case 3: Hardware & Electronic Parts (e.g., small screw boxes, circuit board pouches)Ideal Machine: Roll-Apply Semi-Automatic LabelerWhy it works:

- Blasts through small parts: Roller-fed labels stick to 2cm×1cm screw boxes 40% faster than manual models

- Durable for workshops: Metal construction resists sawdust/dust (no jamming from workshop debris)

- Low maintenance: Minimal moving parts—just wipe down the roller weekly (no costly service calls)

- 4 Mistakes That Waste Your Money

- Buying the cheapest plastic model: $2,800 labelers sound good—until they jam mid-batch during your holiday rush (plastic gears break fast under regular use)

- Forgetting label size limits: Many budget models can’t handle labels narrower than 3cm—double-check before buying (we learned this the hard way with 2cm part tags)

- Skipping after-sales support: A 1-year on-site repair warranty beats a “cheaper” model—if your labeler breaks on a Tuesday, you can’t wait 2 weeks for parts

- Chasing “all-in-one” claims: A labeler that “works for cans, tubes, and boxes” will do none well—stick to a model built for your primary packaging type

- Conclusion BlockFor small businesses, the best semi-automatic labeling machine isn’t the “fanciest” one—it’s the one that fits your daily volume, packaging shapes, and team’s skill level. Start by noting your daily label count and most common package type, then cross-check against the use cases above.

Recent Posts

-

Best Semi-Automatic Labeling Machine for Food Factories: Boost Efficiency & Cut Costs

December 26, 2025

-

Right-Angle Sealing & Suction Labeling Machines for Food Factories | Double Win

December 20, 2025

-

Cost-Effective Labeling Machine Takes Industry by Storm: ±0.05mm Precision at 40% Lower Price

December 5, 2025